Brushless motors are popular in many applications. They come in two types: sensored and sensorless.

Understanding the differences between sensored and sensorless brushless motors can help you choose the right one for your needs. Sensored motors have sensors to monitor the rotor’s position, ensuring smooth performance. On the other hand, sensorless motors rely on back-EMF to detect rotor position, making them simpler and often cheaper.

Both types have their pros and cons, depending on the application. In this blog, we’ll explore the key differences, benefits, and drawbacks of each type. This comparison will help you make an informed decision when selecting a brushless motor for your project. Dive in to learn more about these two motor types and their unique features.

Credit: techweb.rohm.com

Introduction To Brushless Motors

Brushless motors are a fascinating and critical component in many of today’s technologies. If you’ve ever wondered what makes your drone fly smoothly or your electric car run efficiently, brushless motors are often the answer. Understanding their role and distinguishing between sensored and sensorless types can help you make better choices for your projects.

What Are Brushless Motors?

Brushless motors are electric motors that do not use brushes. Instead, they rely on electronic control to switch the current in the windings. This makes them more efficient and longer-lasting compared to brushed motors.

Imagine the frustration of having to replace parts frequently. Brushless motors spare you from this by reducing wear and tear. They offer a smoother performance and are quieter, which is a huge benefit if you’re working on noise-sensitive projects.

Importance In Modern Applications

Brushless motors are everywhere. From drones and electric vehicles to household appliances and industrial machinery, their application is vast. They provide the reliability and efficiency that modern technology demands.

Think about your morning routine. Your electric toothbrush, perhaps even your blender, likely uses a brushless motor. Their ability to run smoothly and efficiently makes your life easier, without you even realizing it.

Have you ever wondered why your drone doesn’t crash mid-air? It’s the brushless motor keeping it stable. These motors allow for precise control, which is crucial in high-stakes environments like robotics and aviation.

Basics Of Sensored Motors

The world of brushless motors is fascinating, especially when comparing sensored and sensorless variants. Sensored motors come with built-in sensors that provide precise control, making them a popular choice in various applications. Understanding the basics of sensored motors can help you decide if they are the right fit for your needs.

How Sensored Motors Work

Sensored motors use built-in sensors to monitor the rotor position. These sensors send real-time data to the motor controller.

This allows the controller to adjust the power delivery accurately. The result is smoother and more precise motor performance.

Typical sensors used include Hall effect sensors, which detect the magnetic field changes as the rotor spins. This data ensures the motor operates efficiently, even at low speeds.

Advantages Of Sensored Motors

Sensored motors offer several key benefits. One of the main advantages is their ability to start smoothly from a standstill.

This is particularly useful in applications requiring precise start-stop control, like electric vehicles or robotic arms. Another significant advantage is improved torque control.

Sensors provide real-time feedback, allowing the motor to deliver consistent torque under varying loads. This makes sensored motors ideal for tasks requiring high precision and reliability.

Have you ever tried using a sensorless motor and felt frustrated with its jerky start? That’s where sensored motors shine, providing a seamless and controlled experience.

So, are sensored motors the right choice for your project? Consider the level of control and precision you need. If smooth operation and accurate torque are crucial, sensored motors could be your best bet.

Basics Of Sensorless Motors

Sensorless brushless motors are a type of electric motor. They don’t use sensors to detect rotor position. These motors rely on the back electromotive force (EMF) generated by the motor. This makes them simpler and often more reliable.

How Sensorless Motors Work

Sensorless motors work by reading the back EMF. Back EMF is the voltage created as the motor spins. The motor controller measures this voltage. It uses this information to adjust the current and keep the motor running smoothly. Without sensors, this method reduces complexity and increases durability.

Advantages Of Sensorless Motors

Sensorless motors have several advantages. First, they are generally more durable. Sensors can fail, but sensorless motors avoid this issue. Second, they are often cheaper. Without sensors, manufacturing costs are lower. Third, they are less complex. Fewer components mean easier maintenance and fewer points of failure. These benefits make sensorless motors ideal for many applications.

Credit: m.youtube.com

Performance Comparison

The performance of a motor is crucial for any application. Understanding the differences between sensored and sensorless brushless motors helps in making the right choice. This section will focus on their efficiency, speed, torque, and control.

Efficiency And Speed

Sensored motors generally offer higher efficiency at low speeds. They use sensors to detect rotor position, ensuring precise control. This precision leads to smooth operation. Sensorless motors, on the other hand, perform better at high speeds. They rely on back EMF to estimate rotor position. This method works well at high RPMs, where efficiency is key.

Torque And Control

Sensored motors excel in providing consistent torque. The sensors allow for better control, especially at low speeds. This makes them ideal for applications requiring precise movement. Sensorless motors may struggle at low speeds. They lack direct feedback, which can lead to torque ripple. At higher speeds, their performance improves significantly. Overall, sensored motors offer better low-speed control, while sensorless motors are suited for high-speed applications.

Applications Of Sensored Motors

Sensored brushless motors are becoming increasingly popular in various fields due to their precision and efficiency. These motors are equipped with sensors that provide feedback about the rotor’s position, making them ideal for applications where control and accuracy are paramount. Let’s explore some common uses of sensored motors.

Rc Cars And Drones

RC cars and drones benefit significantly from sensored brushless motors. Have you ever tried flying a drone and noticed it struggling to maintain stability during sharp turns? Sensored motors can help with that. They provide precise control over speed and torque, which is crucial for these high-speed applications.

In RC cars, sensored motors enhance the driving experience. They offer smoother acceleration and deceleration, giving you better control over your vehicle. This can be the difference between winning and losing in a competitive race.

Industrial Automation

Industrial automation relies heavily on the precision that sensored motors provide. Imagine a robotic arm assembling delicate electronics. Any miscalculation can lead to significant errors. Sensored motors ensure that each movement is accurate and repeatable, minimizing the risk of mistakes.

These motors are also used in conveyor belts, packaging machines, and CNC machines. Their ability to maintain consistent performance under varying loads makes them invaluable in industrial settings. If you are in manufacturing, investing in sensored motors can boost your production efficiency.

What other applications can you think of where precision is key? Sensored motors might just be the solution you need.

Applications Of Sensorless Motors

Sensorless brushless motors have many uses across various industries. Their simplicity and efficiency make them ideal for several applications. Below are some key areas where sensorless motors excel.

Electric Vehicles

Electric vehicles (EVs) benefit greatly from sensorless motors. These motors reduce the overall cost and complexity of the drive system. They are more reliable because they have fewer components. This means less maintenance and longer lifespan.

In EVs, sensorless motors also provide good performance at high speeds. They are efficient and help in conserving battery power. This leads to longer driving ranges. Their compact design is an added advantage in the tight spaces of electric cars.

Consumer Electronics

Consumer electronics often use sensorless motors for their efficiency. Devices like drones, electric scooters, and even some household appliances use these motors. They are light and compact, which is crucial for handheld and portable devices.

Sensorless motors in consumer electronics also contribute to quieter operation. This enhances the user experience. Their efficiency helps in extending battery life, which is crucial for portable devices. The simplicity of these motors ensures a lower chance of failure, making them reliable for everyday use.

Challenges And Limitations

When comparing sensored and sensorless brushless motors, both types present unique challenges and limitations. Understanding these can help in making an informed decision. Let’s explore some key aspects that might influence your choice.

Cost Considerations

Sensored brushless motors are generally more expensive. The extra sensors add to the cost. These sensors require precise installation and calibration. This increases manufacturing expenses. Sensorless motors are simpler. Their lack of sensors makes them cheaper. This makes them more affordable for budget-conscious users.

Maintenance And Durability

Sensored motors demand more maintenance. The sensors can wear out. They may need regular calibration. This can add to the upkeep cost. Sensorless motors are more robust. They have fewer parts that can fail. This makes them more durable in harsh conditions. Less maintenance means more reliable performance.

Future Trends

The future of brushless motors is bright and full of potential. As technology advances, both sensored and sensorless motors are set to benefit from significant improvements. In this section, we’ll explore some of the anticipated trends and innovations that could shape their future.

Technological Innovations

Technological advancements are likely to enhance the performance and efficiency of both sensored and sensorless brushless motors. One area of focus is the development of smarter control algorithms.

These algorithms can optimize motor performance in real time, reducing energy consumption and improving reliability. Imagine your electric vehicle running smoother and longer on a single charge, thanks to these smarter controls.

Another innovation to watch is the integration of IoT (Internet of Things). With IoT, motors can communicate with other devices, providing valuable data on performance and maintenance needs. This means fewer unexpected breakdowns and longer motor life.

Market Growth

The market for brushless motors is growing rapidly. Industries like automotive, aerospace, and robotics are driving this growth. They demand more efficient, reliable, and low-maintenance motors.

You might have seen the rise of electric vehicles (EVs). This is a prime example of how brushless motors are becoming mainstream. As EVs become more popular, the demand for both sensored and sensorless motors will increase.

Additionally, the renewable energy sector is expanding. Wind turbines and solar power systems often use brushless motors. With the world moving towards greener energy, the market for these motors will only grow.

Are you excited about the future of brushless motors? What technological innovation are you looking forward to the most?

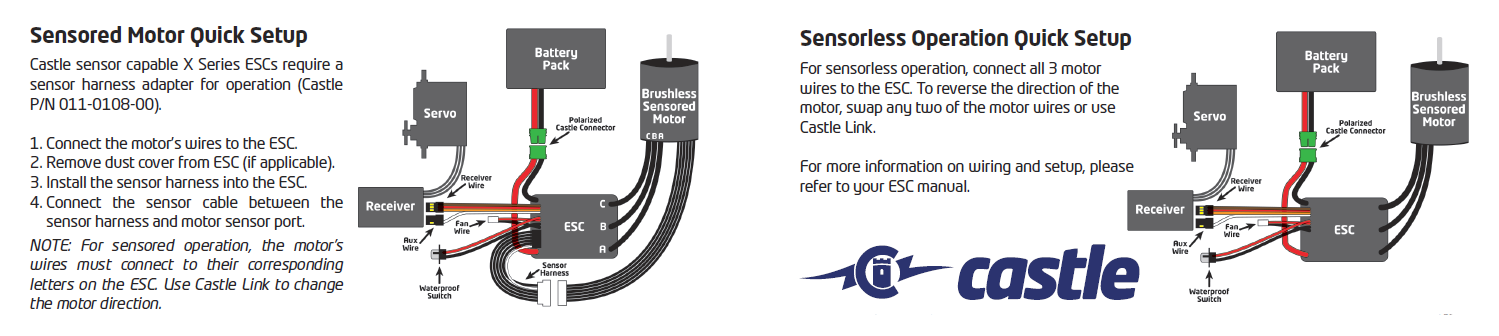

Credit: home.castlecreations.com

Frequently Asked Questions

What’s Better, Sensored Or Sensorless?

Sensored motors provide smoother control and better performance at low speeds. Sensorless motors are more robust and cheaper. Choose based on your needs and budget.

What Are The Benefits Of A Sensored Brushless Motor?

Sensored brushless motors offer precise control, efficient performance, and smoother operation. They excel in low-speed torque and eliminate cogging. Ideal for applications requiring accuracy.

Can You Use A Sensored Motor With Sensorless Esc?

No, you cannot use a sensored motor with a sensorless ESC. The ESC lacks the necessary connections for the sensors.

How Does A Sensorless Brushless Motor Work?

A sensorless brushless motor uses back electromotive force (EMF) to determine rotor position. This eliminates the need for sensors. The controller reads the EMF signals to adjust the motor’s power supply, ensuring efficient operation.

What Is A Sensored Brushless Motor?

A sensored brushless motor uses sensors to monitor rotor position. This helps in precise control and smoother operation.

Conclusion

Choosing between sensored and sensorless brushless motors depends on your needs. Sensored motors offer precise control. They are great for tasks requiring accuracy. Sensorless motors, on the other hand, are simpler and lighter. They suit high-speed applications well. Both have unique advantages.

Consider your project requirements and budget. Making the right choice will enhance your motor’s performance.