Brushed and brushless motors are common in many devices. They power everything from toys to power tools.

Understanding their differences can help you make better choices. Choosing between brushed and brushless motors depends on several factors. Both types have their unique advantages. Brushed motors are simpler and cheaper. Brushless motors, on the other hand, offer better efficiency and longer life.

This blog will help you understand both types of motors. We’ll explore how they work, their benefits, and their drawbacks. By the end, you’ll know which motor suits your needs best. Whether you are a hobbyist or a professional, this comparison will guide you. Let’s dive into the details of brushed vs brushless motors.

Credit: www.youtube.com

Introduction To Motor Types

Motors power many devices in our daily lives. From household appliances to electric vehicles, motors are crucial. There are two main types: brushed and brushless motors. Understanding their basics can help make informed choices.

Basics Of Brushed Motors

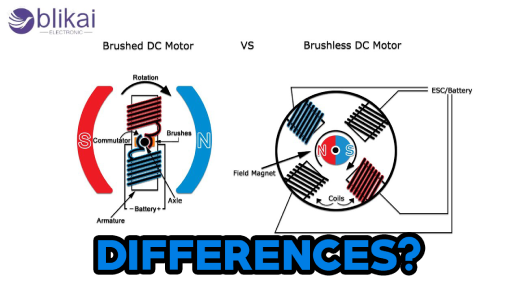

Brushed motors are simple in design. They have been around for many years. A brushed motor uses brushes to deliver current to the commutator. This creates the electromagnetic field that makes the rotor spin. These brushes wear out over time. This leads to maintenance needs. Brushed motors are usually cheaper. They are often found in basic toys, small appliances, and some power tools.

Basics Of Brushless Motors

Brushless motors are more advanced. They do not use brushes. Instead, they use an electronic controller to switch the current. This reduces wear and tear. Brushless motors are more efficient and have a longer lifespan. They also generate less heat. These motors are common in high-end power tools, drones, and electric vehicles. They are often more expensive but offer better performance and reliability.

How Brushed Motors Work

Brushed motors use a commutator and brushes to deliver current to the motor windings. This creates rotational motion. Brushless motors, on the other hand, use electronic controllers for the same purpose, offering greater efficiency.

Brushed motors have been around for a long time. They power many devices and are known for their simplicity and reliability. Understanding how these motors work helps in choosing the right motor for your needs.Components Of Brushed Motors

A brushed motor has a few key parts. The stator is the stationary part. It creates a magnetic field. The rotor, or armature, rotates inside the stator. This part has coils of wire. The brushes and commutator make electrical contact. They transfer current to the rotor.Operation And Functionality

The motor works by passing current through the brushes. This current flows into the commutator and then into the rotor’s coils. The magnetic field in the stator interacts with the current in the rotor. This interaction creates a force. This force makes the rotor turn. The brushes switch the current direction. This keeps the rotor spinning in the same direction.Brushed motors are easy to control. They only need a simple power source. They are also cheaper to produce. But, they have some drawbacks. The brushes wear out over time. This means they need regular maintenance. They also create more noise and electrical interference.Understanding these basics helps in making informed decisions. Knowing the components and how they work is crucial. It ensures you choose the best motor for your application. “`How Brushless Motors Work

Understanding how brushless motors work can seem complex. But breaking it down makes it easier. Brushless motors are more efficient and durable than brushed motors. They have fewer moving parts and use electronic commutation.

Components Of Brushless Motors

Brushless motors have several key components. These include the stator, rotor, and electronic speed controller (ESC). The stator holds the windings. The rotor contains the magnets. The ESC controls the motor’s speed and direction.

Operation And Functionality

The operation of brushless motors involves the ESC sending current to the stator. This creates a rotating magnetic field. The rotor follows this field, causing the motor to spin. Sensors track the rotor’s position. The ESC adjusts the current based on this position. This ensures smooth and precise control.

Brushless motors are known for their efficiency. They produce less heat and have a longer lifespan. Their design reduces wear and tear. This makes them ideal for many applications.

Performance Comparison

Brushed and brushless motors are used in many applications, from power tools to electric vehicles. Each type has its strengths and weaknesses. This section will compare their performance in terms of efficiency, power, speed, and torque.

Efficiency And Power

Brushless motors are generally more efficient than brushed motors. They use electronic controllers to manage power distribution. This results in less energy loss and better overall efficiency. Brushless motors also produce more power. They can handle higher speeds and heavier loads without overheating.

Brushed motors, on the other hand, have physical brushes that create friction. This friction reduces efficiency and limits power output. Brushed motors are simpler and cheaper but less efficient and powerful.

Speed And Torque

Brushless motors excel in speed and torque. They can reach higher speeds due to their efficient design. The lack of brushes means less mechanical resistance. This allows brushless motors to spin faster and maintain higher torque levels.

Brushed motors have lower speed and torque capabilities. The brushes wear out over time, reducing performance. They are suitable for applications requiring moderate speed and torque. Brushless motors are preferred for high-performance needs.

Durability And Maintenance

Understanding the durability and maintenance of brushed and brushless motors is vital. It helps in choosing the right motor for your needs. Let’s dive into the lifespan of each motor type.

Lifespan Of Brushed Motors

Brushed motors have a shorter lifespan. They rely on brushes to transfer power. These brushes wear out over time. Regular maintenance is necessary. Brushes need replacing periodically. This adds to the upkeep costs. Dirt and dust can enter the motor. This can cause further wear and tear.

Lifespan Of Brushless Motors

Brushless motors last longer. They do not have brushes that wear out. This reduces the need for frequent maintenance. The absence of brushes means less friction. Less friction results in less heat. This enhances the motor’s lifespan. Brushless motors are also sealed. They are less prone to dirt and dust.

Credit: www.blikai.com

Cost Considerations

Brushed motors are generally cheaper upfront but may require more maintenance over time. Brushless motors have higher initial costs but offer better efficiency and durability. Consider long-term expenses when choosing between the two.

When you’re deciding between brushed and brushless motors, cost considerations play a significant role. It’s not just about the upfront price but also the expenses you’ll encounter over time. Let’s dive into the financial aspects of each motor type.###Initial Investment

The initial investment for brushed motors is generally lower. They are cheaper to manufacture and, therefore, less expensive to purchase. This makes them a popular choice for budget-conscious consumers.However, brushless motors, while more expensive upfront, come with their own set of advantages. Their higher price tag often reflects better technology and longer-lasting components. If you’re planning for a high-performance application, this initial cost might be worth it.###Long-term Costs

Long-term costs are where brushless motors often outshine brushed ones. Brushed motors require frequent maintenance. You’ll need to replace brushes and commutators, which can add up over time.Brushless motors, on the other hand, have fewer wearable parts. They require less maintenance, resulting in lower long-term costs. This can be a significant saving if you plan to use the motor extensively.When I first switched to a brushless motor for my DIY drone, I noticed a big difference. I spent less time and money on upkeep, freeing me up to focus on more enjoyable projects.So, ask yourself: Do you prefer a lower initial cost with more ongoing expenses, or are you willing to invest more upfront for minimal maintenance later?By understanding both the initial investment and long-term costs, you can make a more informed decision that suits your needs and budget.Applications And Use Cases

Brushed motors are ideal for affordable, low-maintenance applications. Brushless motors offer higher efficiency and durability, suitable for advanced technology and demanding tasks. Both have unique advantages in various industries.

When it comes to motors, understanding their applications and use cases can be crucial in making the right choice for your project. Brushed and brushless motors each have their own unique strengths and weaknesses, making them suitable for different tasks. Let’s dive into where each type excels.Common Uses For Brushed Motors

Brushed motors are often used in applications that require simple control and lower cost. You’ll find them in household appliances like blenders and fans. These motors are also prevalent in toys and basic hobby projects, where the ease of wiring and control is a plus.In my first DIY robot project, I chose brushed motors because they were inexpensive and easy to integrate. They got the job done without complicating the build.Another common use is in automotive applications such as windshield wipers and power windows. The simplicity and reliability of brushed motors make them ideal for these repetitive tasks.Common Uses For Brushless Motors

Brushless motors, on the other hand, are preferred for their efficiency and longevity. They are often used in high-performance areas like drones and electric vehicles. These motors provide more power and run cooler, which is essential for demanding tasks.In my experience with drone building, switching to brushless motors made a huge difference. The flight time increased, and the performance was noticeably better.You’ll also find brushless motors in computer hard drives and cooling fans. Their precise control and durability are perfect for tasks that require consistent and reliable operation.Brushless motors are increasingly used in industrial applications such as conveyor belts and robotics. Their efficiency and low maintenance make them a smart choice for long-term projects.Which type of motor do you think suits your needs best? Whether it’s the simplicity of brushed motors or the efficiency of brushless ones, understanding their applications can help you make an informed decision.Choosing The Right Motor

Choosing the right motor can feel overwhelming. Brushed and brushless motors have different benefits. Understanding these differences helps you pick the perfect motor for your needs.

Assessing Your Needs

First, think about your project. What do you need the motor to do? For simple tasks, a brushed motor might be enough. These motors are cheaper and easier to maintain.

For more complex tasks, consider a brushless motor. These motors are more efficient and last longer. They use less energy and perform better under heavy loads. Think about the power source. Brushless motors work better with batteries. They are ideal for drones and electric cars.

Making An Informed Decision

Compare the costs. Brushed motors are cheaper upfront. They might need more maintenance over time. Brushless motors cost more, but they last longer. They need less upkeep.

Consider the environment. Brushless motors are better for rough conditions. They resist dust and moisture. Brushed motors can struggle in harsh environments. Think about noise. Brushless motors are quieter. This can be important for indoor use.

Finally, read reviews. Learn from other users’ experiences. Their insights can help you make the best choice.

Future Trends

The future of brushed and brushless motors is full of exciting possibilities. With advancements in technology and emerging applications, these motors are set to become even more efficient and versatile. Let’s dive into the trends that will shape their future.

Advancements In Motor Technology

Motor technology is evolving rapidly. Brushless motors are becoming more compact and powerful. This makes them ideal for various applications.

Innovations like improved magnetic materials and better cooling systems are enhancing performance. You can expect motors to run longer and require less maintenance.

Manufacturers are also focusing on energy efficiency. Brushless motors are leading the way in reducing energy consumption. This is great news for your electricity bills and the environment.

Emerging Applications

Brushless motors are finding new applications every day. Drones are a prime example. Their lightweight and efficient design make them perfect for aerial photography.

Electric vehicles are another growing field. Brushless motors provide the torque and efficiency needed for longer drives. Imagine your car running smoother and longer with less energy.

Even household appliances are getting an upgrade. Brushless motors are making vacuum cleaners quieter and more powerful. Think about how much easier cleaning will become.

What trends do you think will shape the future of motor technology? Share your thoughts in the comments below!

Credit: solonz.co.nz

Frequently Asked Questions

Are Brushless Motors Better Than Brushed Motors?

Yes, brushless motors are better than brushed motors. They offer higher efficiency, longer lifespan, and require less maintenance.

What Are The Disadvantages Of A Brushless Motor?

Brushless motors are more expensive than brushed ones. They require complex electronic controllers. Maintenance can be challenging due to their design.

Why Are Brushed Motors Still Used?

Brushed motors are still used because they are cost-effective, simple to control, and reliable for various applications. They offer high torque at low speeds and are easy to maintain.

What Are The Disadvantages Of Brushed Dc Motors?

Brushed DC motors have several disadvantages. They require frequent maintenance due to brush wear. They generate electrical noise. They have lower efficiency and shorter lifespans. Brushes can cause sparking, posing safety risks. Their performance degrades over time.

What Is The Difference Between Brushed And Brushless Motors?

Brushed motors use brushes for current flow. Brushless motors use electronic controllers.

Conclusion

Choosing between brushed and brushless motors depends on your needs. Brushed motors are cost-effective and simple. Brushless motors offer efficiency and durability. For high-demand tasks, brushless is the better choice. For basic tasks, brushed motors suffice. Assess your project requirements and budget.

Then, make your decision. Understanding these differences helps you pick the right motor. This ensures your tools perform efficiently.